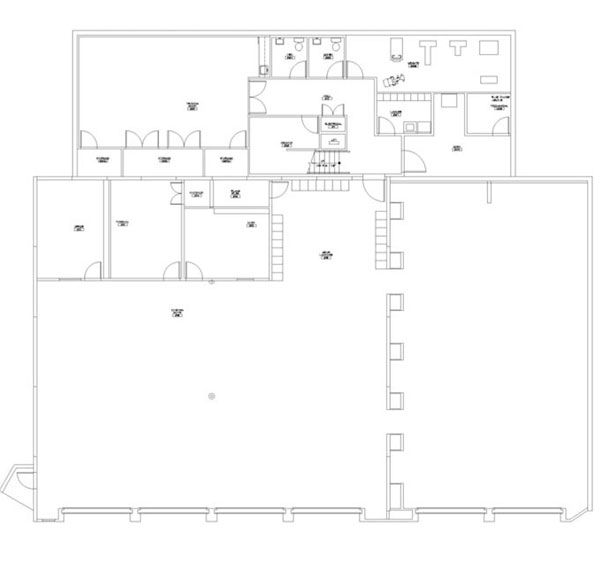

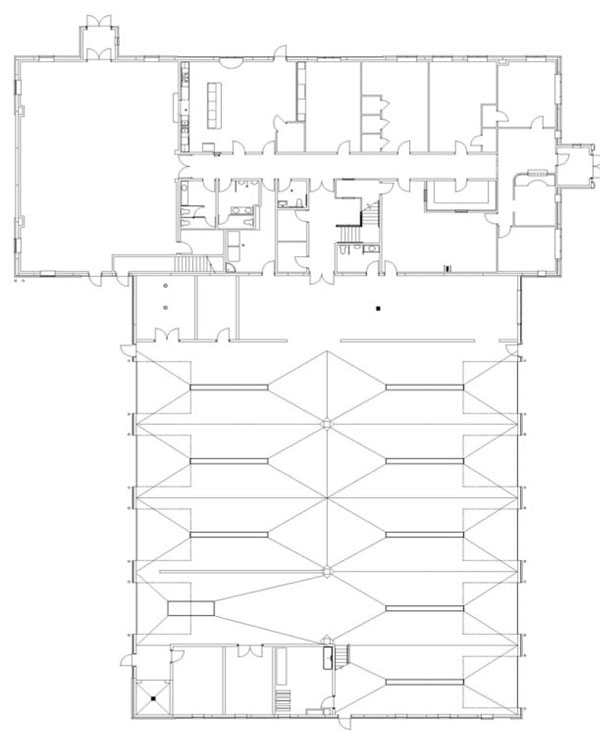

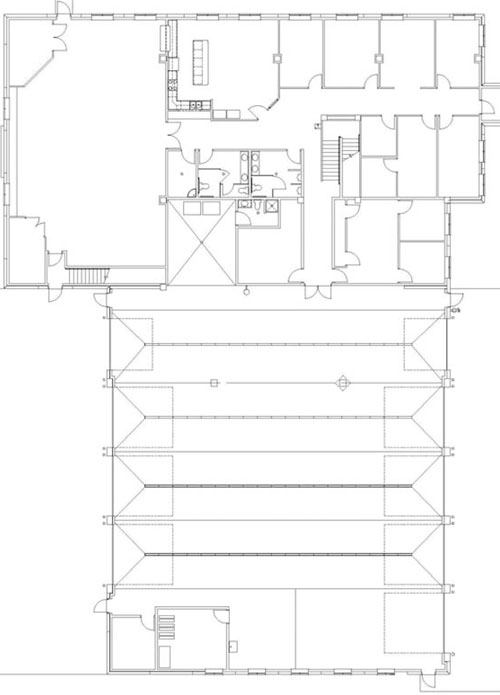

Eagle County School District East Bus Barn

Rader Engineering provided heating and ventilation upgrades to the Eagle County School District East Bus Barn to improve both comfort and efficiency. The existing garage exhaust fan airflow was adjusted to meet code. A standby exhaust fan was added to provide minimum ventilation when the large garage exhaust fan was not needed, which reduced energy consumption from fans and heating costs. The existing standard efficiency unit heaters were replaced with high efficiency unit heaters. Destratification fans were added to blow warm air down from the ceiling to reduce unit heater run time.