Brightwater Outfitters

Location: Gypsum, CO

Project Description:

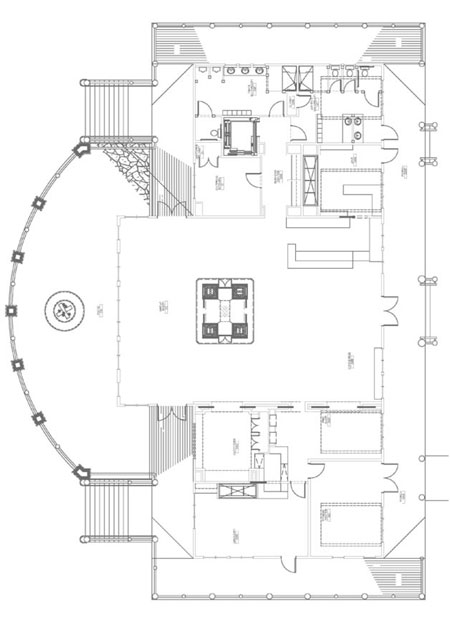

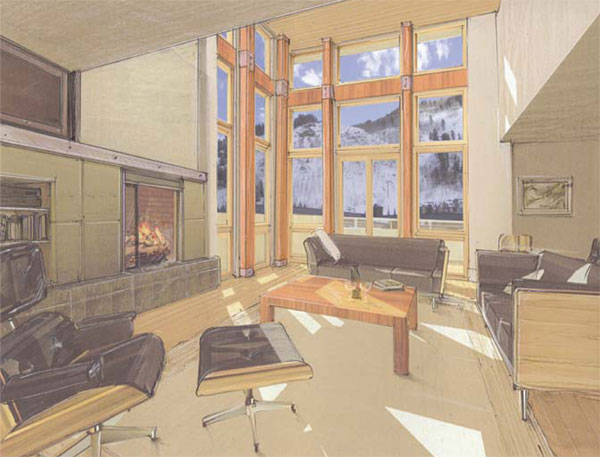

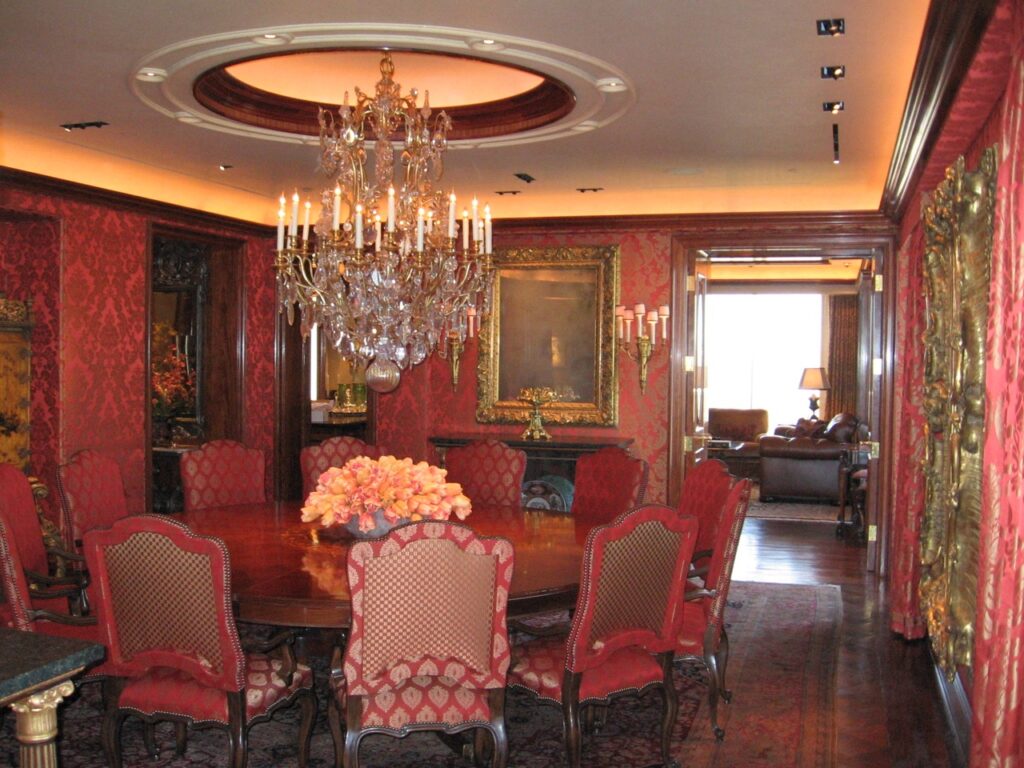

The Outfitter’s Post is located at the heart of the Brightwater Club Village and is an Amenity Building for the members and guests. Amenities include a Living Room, Post Office, Grocery Store, Fitness Center and Golf Cart Storage.

Rader Engineering provided full Mechanical, Electrical and Plumbing Engineering design services for the project. The detailed design was fully coordinated with the other project consultants, including the Architect, Structural Engineer, Civil Engineer and Kitchen Consultant.

The MEP systems designed for the building include full air conditioning throughout via fan coils and a central chiller, radiant floor heating, snowmelting and a high efficiency boiler plant. Due to the hydrogen off-gassing from the batteries of approximately 70 golf carts, an exhaust and supply ventilation system was designed with sophisticated controls and sensors to ensure levels were maintained below the lower explosion levels.

Highlights from the plumbing system include the long linear trench drains in the cart area to collect water and debris from the carts and from the washing area. Sediment basins and a sand oil separator ensure the drainage system is kept clean and operable. A lift

station was required for all lower level plumbing fixtures due to the invert elevation of the main sewer line.