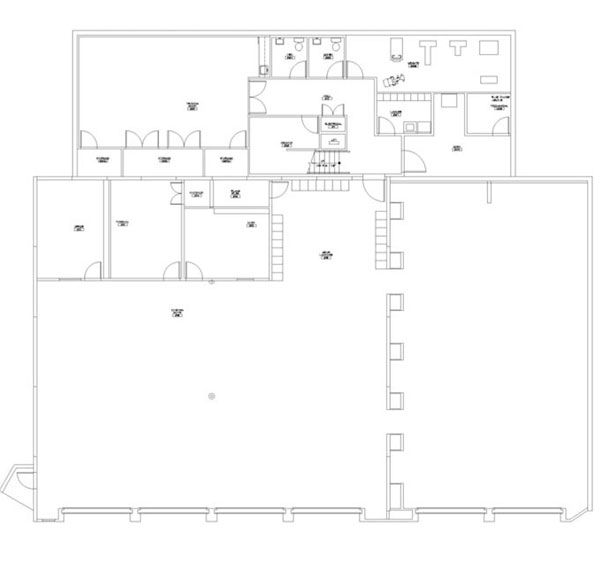

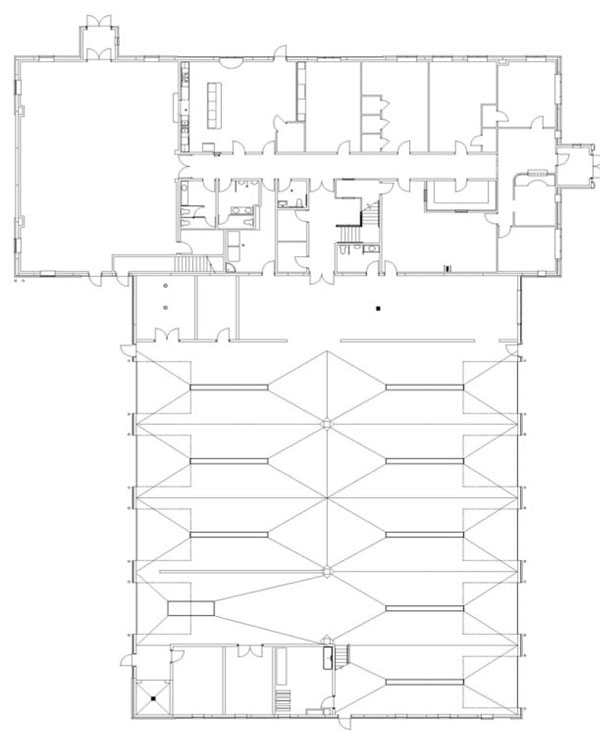

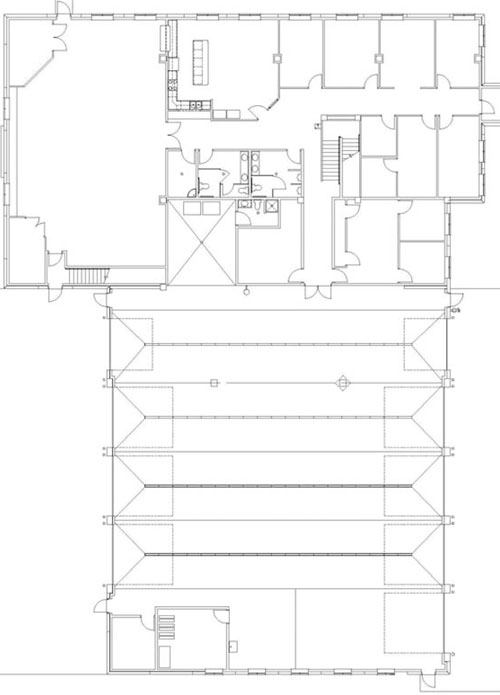

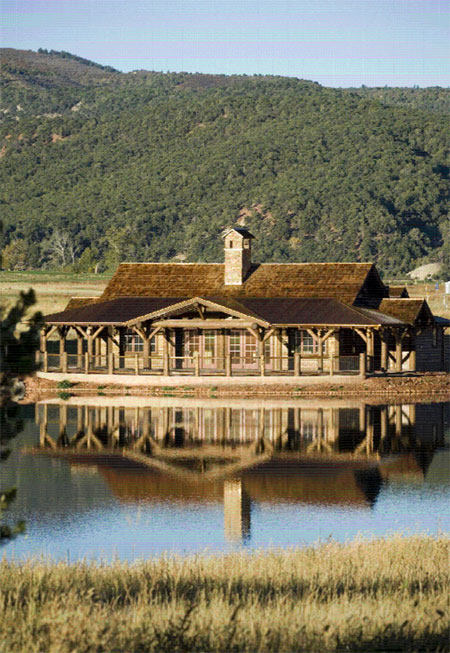

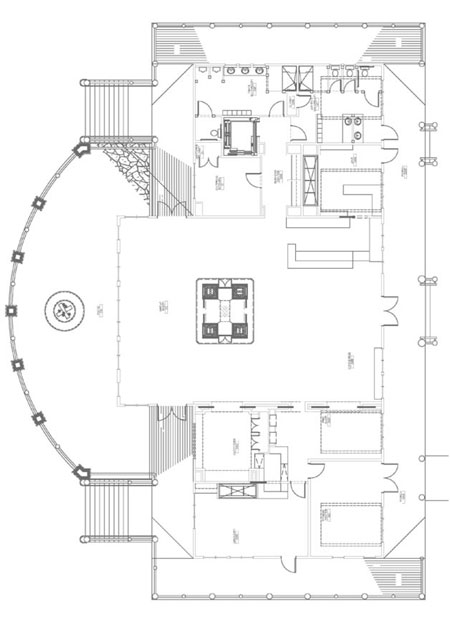

Sweetwater Grill — Steamboat Springs, CO

Location: Steamboat Springs, CO

Project Description:

Rader Engineering provided full mechanical and plumbing engineering services for this major restaurant renovation project. The building’s HVAC systems were fully upgraded and now include new forced air heating and cooling throughout, provided by fan coils. The fan coils are served by a high efficiency boiler and high SEER condensing units for heating and cooling, respectively. Ventilation is provided by an Energy Recovery Ventilator for efficient and balanced air exchange. The kitchen exhaust systems were also upgraded with new ductwork, new exhaust fans and a new dishwasher exhaust hood. Other energy efficient measures included in the design and installation are occupancy sensors located in the bathrooms, which allow the lights and exhaust fan to run only when occupants are present. Due to the close proximity of the building to the Yampa River (approximately 5 feet), Rader designed a few safety measures for the building including a sump pump and watertight ductwork in the crawl space as well as the inclusion of backwater valves on sewer piping.