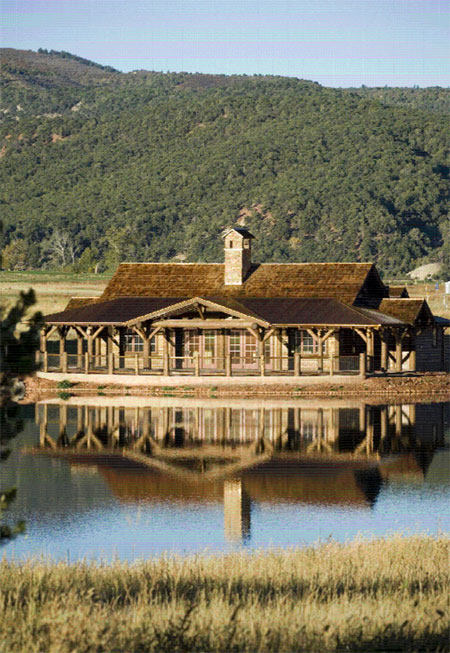

Brightwater Lakehouse

Location: Gypsum, CO

Project Description:

The Lakehouse Building is located at the heart of the Brightwater Club Village and is the dining destination for the residents of the gated community, as well as for golfers playing the Robert Trent Jr. designed golf course.

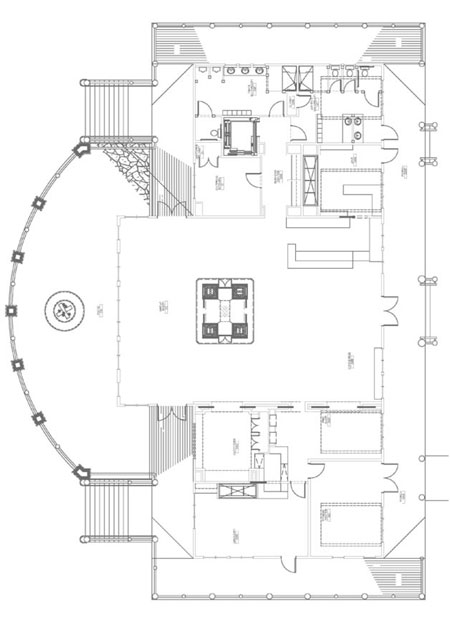

Rader Engineering provided full Mechanical, Electrical and Plumbing Engineering design services for the project. Much of the design centered around the commercial kitchen, which included grease hood exhaust, dishwasher hood exhaust, hood fire suppression specification, water heater and grease trap design. A direct-fired make-up air unit was used to efficiently replace the large volumes of air being exhausted from the kitchen hoods. This make-up air unit is also equipped with an evaporative cooling

module to provide energy efficient cooling for the kitchen. The Dining area is served by a heating and cooling furnace unit that also provides outside air for code ventilation and indoor air quality. The furnace has two zones allowing for greater comfort control. Additional exhaust is provided for the bathrooms, toilet rooms, janitor closet and crawl space.